All About Vibratory Deburring

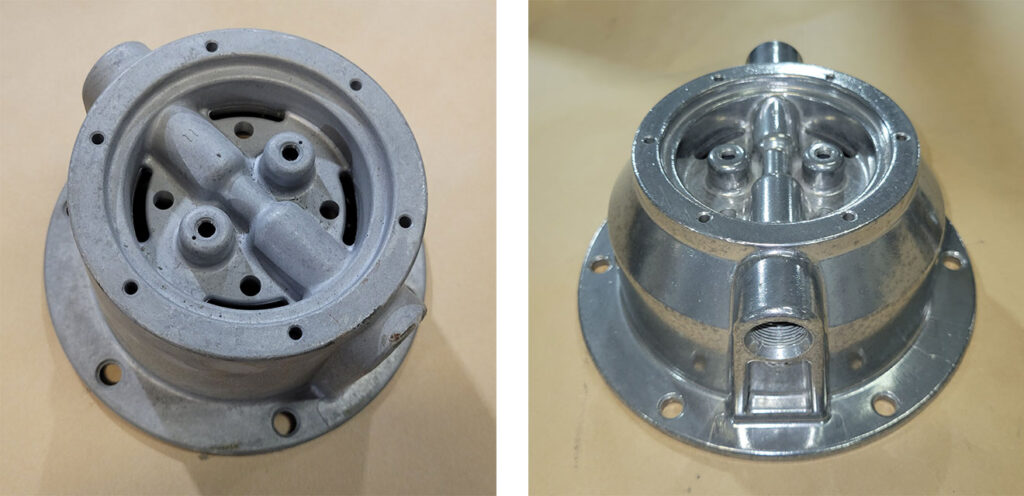

In the realm of metal finishing, precision and surface finish are paramount to achieving high-quality components. However, the machining processes that produce these components often leave behind sharp edges and burrs, imperfections that can compromise functionality and safety.

This is where vibratory deburring steps in, offering a versatile and efficient solution for smoothing out rough surfaces and removing burrs.

What is vibratory deburring?

Vibratory deburring is a mass finishing process that utilizes a tumbling chamber filled with abrasive media to smooth and polish metal parts. The chamber is vibrated, causing the media to move in a swirling motion and interact with the parts, effectively removing burrs, sharp edges, and surface imperfections. Vibratory deburring finds application in a variety of industries, including automotive, aerospace, medical, electronics, and more.

How does vibratory deburring work?

The effectiveness of vibratory deburring lies in the combination of vibration and abrasive media. As the chamber vibrates, the media particles collide with the parts, gradually abrading away burrs and irregularities. The specific type of media used depends on the material of the parts and the desired finish. The expert finishers at Microfinish can recommend the best media for your project.

What are the benefits of vibratory deburring?

- Eliminates burrs and sharp edges. This enhances the safety and functionality of machined components.

- Achieves consistent surface finish. Vibratory deburring produces a uniform and smooth surface finish, improving the appearance and performance of parts.

- Reduces material waste. By smoothing out irregularities, vibratory deburring minimizes material removal, leading to cost savings.

- Improves efficiency. Vibratory deburring can process multiple parts simultaneously, making it a highly efficient mass finishing method.

- Vibratory deburring can be applied to a wide range of materials, including metal, plastic, and even some composites.

Vibratory deburring is an essential process that ensures the precision and surface quality of machined components. Its versatility, efficiency, and ability to handle a wide range of materials make it an invaluable tool for various industries. Microfinish has performed superior vibratory deburring as part of our metal finishing services. Our vibratory deburring process means consistent and uniform results that is cost effective and time efficient.

Call Microfinish today at (314) 849-8181 to learn more about how our vibratory deburring services can make a positive impact for your company and parts or to receive a no-obligation price quote. See what our St. Louis parts finishing team can accomplish for you with the quality and perfection that comes with over 60 years of experience. After all, we are here to the finish!